Formula 1, often dubbed as the pinnacle of motorsport, is a world where speed, precision, and technology converge. While millions of fans watch in awe as these high-performance machines zoom around the racetrack, there’s a question that has intrigued many: How do you start an F1 car? It’s a query that pops up at family gatherings, dinner conversations, and casual chats among friends who may not be die-hard fans of the sport. In this article, we’re going to delve deep into the intricate process of starting an F1 car, unraveling the technical marvel that lies beneath the surface. So, buckle up as we explore the fascinating journey from a cold engine to a roaring beast on the racetrack.

Also Read: What Would Happen if the Moon Disappeared: The Catastrophic Effects

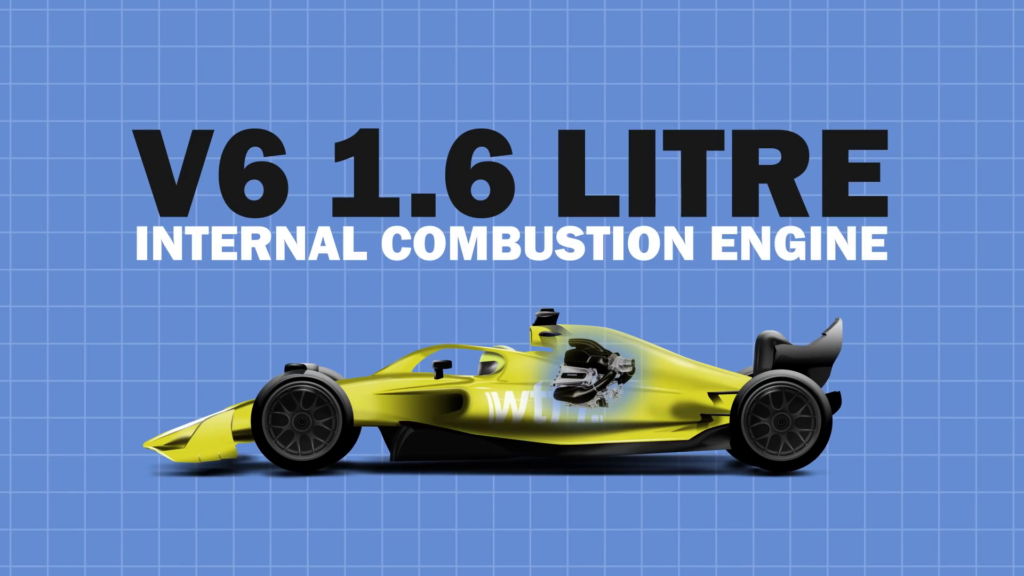

The Complex Power Unit: Heart of the Beast

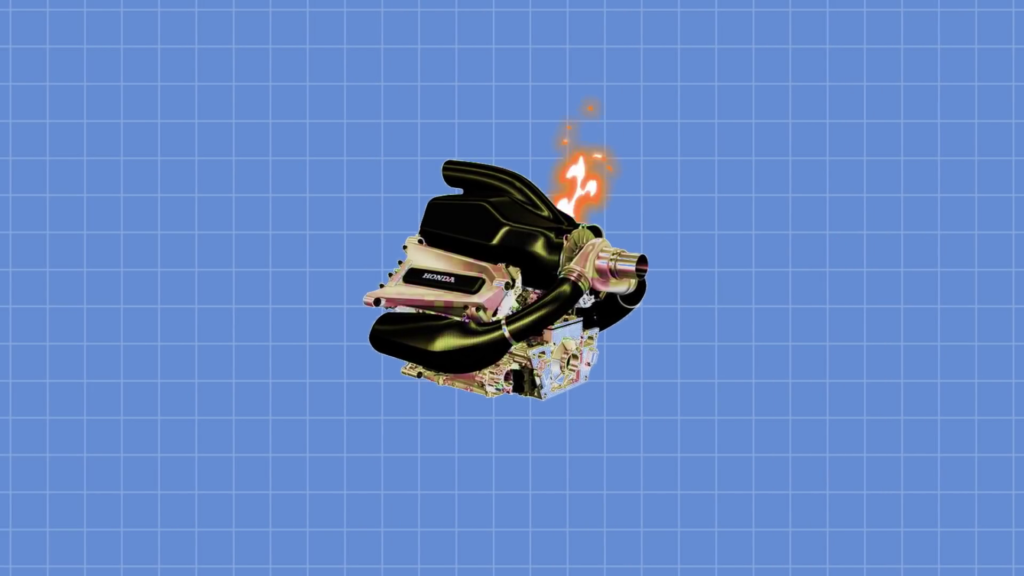

At the heart of every Formula 1 car lies a highly sophisticated power unit. This power unit is a technological masterpiece, comprised of six distinct components, with the engine being just one of them. Since the introduction of new regulations in 2014, Formula 1 teams have been required to use a V6 1.6-liter internal combustion engine, often referred to as ICE. However, the power unit is far more than just the engine.

- Turbocharger: One of the critical components is the turbocharger, responsible for controlling the density of air supplied to the engine. It plays a vital role in maximizing engine efficiency and power output.

- MGU-K (Motor Generator Unit Kinetic): The MGU-K is a compact yet powerful device that harvests and stores energy during braking. This energy iz then Stored into the batteries.

- MGU-H (Motor Generator Unit Heat): The MGU-H is another component designed to recover energy, but in this case, it captures energy from the heat generated by the exhaust. This energy then store into the battery and later this energy will use to power the control electronics and MGU-K unit.

- Energy Store: It’s basically the battery of the Irfan car all the harvested energy from the MGU-K and MGU-H stores here. This energy will later use to provide acceleration or other functions.

- Control Electronics: Often considered the car’s brain, the control electronics manage and govern the power unit’s functions. They ensure everything operates seamlessly and efficiently.

With these components working in harmony, the power unit is a true marvel of engineering. However, starting it is far from a simple turn of a key or push of a button, as some might imagine.

How Formula 1 Engine Start From Cold to Hot?

Starting a Formula 1 car is a meticulous process that requires a team of engineers and technicians to orchestrate. Here’s a step-by-step breakdown of the intricate ritual that transforms a cold engine into a roaring beast:

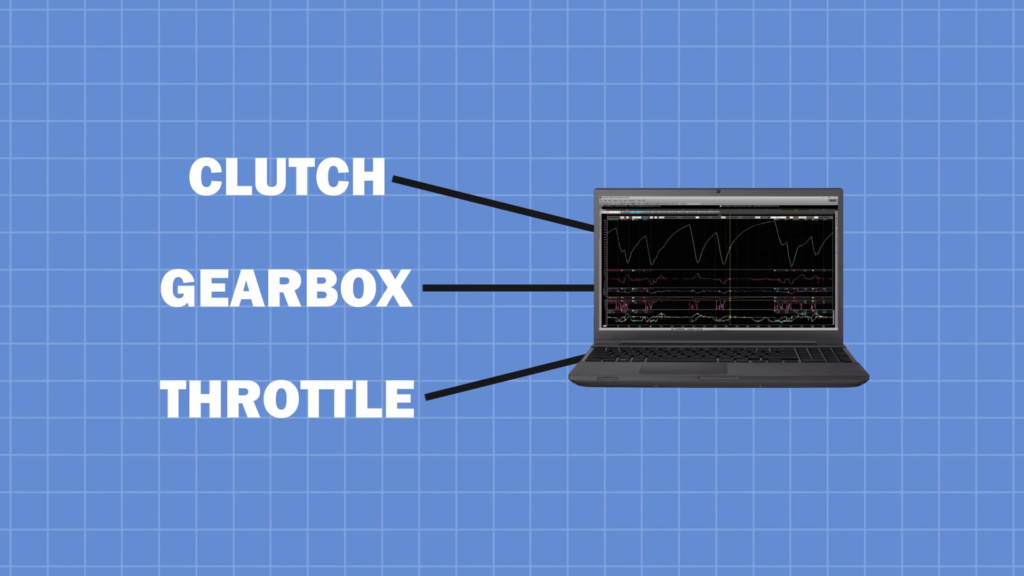

Step 1: Laptop Connection

The process begins with engineers connecting their laptops to the engine control units using specialized cables. These cables link the clutch, gearbox, and throttle to the laptops, enabling engineers to monitor data from various parts of the power unit.

Step 2: Engine Temperature Management:

Before even thinking about starting the engine, it’s crucial to bring it up to the right temperature. Starting a cold engine is not an option in Formula 1 cars. To achieve this, the engine undergoes a careful warming process.

Imagine it like preheating an oven before baking a pizza. Just as you wouldn’t toss a pizza into a cold oven, Formula 1 engines can’t operate efficiently until they’re at the optimal temperature.

If it is tried to turn on the engine at cold state the engine may chocked or be damaged in this process, these engine components are so compact, If the temperature is not similar or adequate in every part of the engine the engine will destroy. F1 engines cannot regulate their temperature independently. Thus, before starting, the engine must be brought up to the optimal temperature.

Step 3: Coating with Hot Oil:

To take the engine’s temperature into certain degrees and to coat its internal components hot engine oil come into play. This process helps prevent excessive wear and tear due to friction, which can be a concern given the high precision and compactness of the engine’s parts.

To achieve this, an external hot coolant circulating pump comes into play. This pump, mounted on a trolley, connects to the engine via two plugs on the coolant passages. It circulates hot oil through hoses and into the engine, ensuring a uniform distribution.

Step 4: Compressed Air and Additional Heating

As the engine’s warming continues, compressed air is pumped in to offset potential leaks in the pneumatic valves during the engine’s initial startup. It’s a measure taken to ensure a smooth and reliable ignition.

In tandem with this, the engine oil undergoes gradual heating through a warming pump operated by another technician. Temperature control is crucial here to avoid oil-related issues. Too low a temperature and the oil won’t lubricate the engine correctly, too high, and it can lead to detrimental hot spots within the oil and ultimately damage the oil.

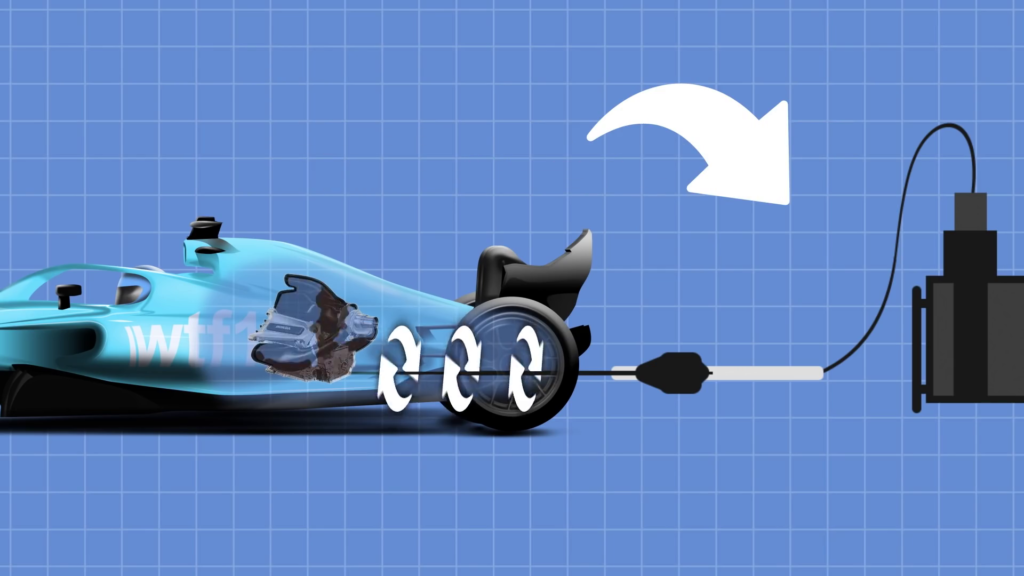

Step 5: External Starter Motor:

Now, the stage is set to initiate the startup sequence. A substantial external starter motor, resembling a large electric screwdriver, is connected to the engine via a rod inserted through an opening. This starter motor is essential for jump-starting the engine’s crankshaft and ensuring that the hot oil is adequately distributed for lubrication. First, starter motor just rotate the engine not start it, because of this controlled rotation all the hot oil spreads throughout the engine, when oil is spread temperature is settled properly at every part of the engine then F1 engineers start the engine.

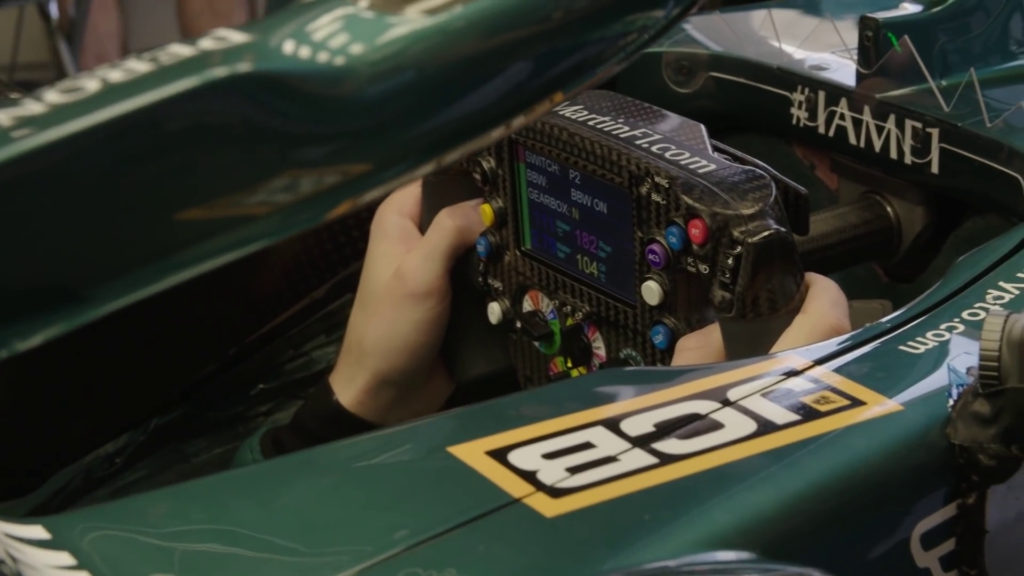

Step 6: Engine Control

With everything in place, it’s finally time to start the engine. However, the engine remains in neutral, no gear is engaged. It’s crucial to prevent accidental ignition. Now the engineer’s laptop comes into play. They control the engine’s startup sequence through the engine control units. When the control switch is off, it acts as a failsafe to prevent accidental firing.

Step 7: Cockpit Activation

Inside the cockpit of the car, a crew member uses the buttons on the steering wheel to activate the fuel systems and ignition. It’s a crucial step in the startup process.

Step 8: Crank and Checks

As the starter motor cranks the engine, the team carefully monitors the startup process. The engine is allowed to run for a brief period to ensure that the oil is heating up and properly draining into the oil tank. This is assessed through an electronic oil level sensor inside the oil tank, which provides real-time data to the engineers’ screens.

Step 9: Driver Assessment

Finally, after the engine has been brought to life and thoroughly checked, the driver takes the wheel. They assess the engine’s feel and performance from within the cockpit, ensuring everything is in perfect working order.

What If an F1 Car Stalls at the Track?

So, if a car stalls on the track, what happens? To be honest, if a car stalls on the track, it generally can’t be restarted and driven back onto the race. Leads to the disqualification of the driver. However, there’s a system come in place called “anti-stall.”

If for some reason, the engine revs drop too low, the F1 car’s computer automatically detects it and engages the clutch. This process is incredibly quick, but there have been instances where an F1 car has come to a stop on the track.

Why Start-Up Systems Are Not Included in the F1 Cars?

Now, a question might arise: why aren’t all these systems installed inside the car? Well, the answer is quite simple. These systems are only necessary when the car is running. When the car is racing on the track, there’s no need for them. So, F1 engineers don’t install unnecessary systems that would only add weight to the car and serve no purpose on the track.

By the way, F1 car engines are so powerful that even the starter motor needs to be extremely powerful, which would add a lot of weight to the car. That’s why I mentioned the weight aspect.

Don’t Miss: Benefits of Credit Cards: Use Wisely to Get the Real Advantages

Conclusion

In the world of Formula 1, starting a car is far more than a simple turn of a key or a push of a button. It’s a meticulously choreographed symphony of technology, engineering, and teamwork. From warming the engine to ensuring precise control, every step in the process is essential to unleash the full potential of these high-performance machines.

So, the next time you watch a Formula 1 race and witness the thunderous roar of the engines as they come to life, you’ll have a deeper appreciation for the complex ballet that occurs behind the scenes. Starting an F1 car is a true testament to the marriage of man and machine, where technology and human expertise combine to create a spectacle unlike any other in the world of sports. Did you ever imagine it would be this intricate? Let us know your thoughts in the comments below.