Just 5.5 lakh for a house seemed unimaginable before, but now it’s possible. 3D printing is a technology with limitless possibilities, and today it’s being used in building projects. It saves time, significantly reduces labor costs, and is environmentally friendly, not disturbing neighbors. Yes, the printers are quite silent too.

India’s first 3D printed house was built at the Indian Institute of Technology Madras campus in Chennai in 2021, inaugurated by Finance Minister Nirmala Sitharaman. Spread across 600 square feet, this house was built in just 21 days by an Indian startup named Tvasta Construction. The total cost of this project was 5.5 lakh, which is only 20% of the standard 2 BHK construction cost.

3D Printing in Construction: How it Works?

In 3D printing construction, specific materials are deposited layer by layer in 3 dimensions. Walls, floors, and roofs are built using this technique. A massive 3D printer completes this task, designed to handle various construction materials like concrete, polymer, sand, gravel, aggregates, and more. A special adhesive is used in the concrete mix to strengthen the layer-by-layer joints. Essential supports and reinforcements are placed during printing, which is the only manual part. After each layer, a brief period is needed for the previous layer to solidify before the next one is added.

If 3D printing is used in construction, it leads to an 80% reduction in waste, a significant reduction in labor requirements, and much shorter construction times. It has been calculated that 3D printing generates only one-third of the waste compared to conventional building methods.

Typically, it takes 4 months to build a 2000 square feet house, excluding tasks like blueprinting, setting up power and light, windows, and other finishing work. If 3D printing is used instead of traditional methods, the same task can be completed within 7 to 10 days. So, 3D printing is not only affordable but also allows for deep personalization. It enables the creation of designs that were previously unimag inable with traditional construction methods.

L & T Builds India’s First 3D Printed Post Office

Two years after this project, Larsen and Toubro (L&T) completed another project – a 3D printed post office named Ulsoor Bazaar Post Office, spanning 1021 square feet. This project was completed in just 43 days with a total cost of 23 lakhs. Although the project incurred costs, there was a significant reduction of 30 to 40 percent in construction time. However, in my opinion, this technology is a blow to laborers, as only 25 to 30 people were involved in completing the entire project. Just think about how many laborers would be required to build a building.

Advantages & Other Factors

According to L&T, apart from construction time, there is no significant cost advantage in this project compared to traditional methods. However, it’s worth noting that the unique look achieved with 3D printed structures is not possible with standard construction methods. While the construction cost remains nearly the same according to L&T, according to Cobod, who developed the printer for this project, the construction cost was reduced by 40% using 3D printing. Here, there seems to be a conflict in statements, but I’m telling you the truth.

Cobod’s Bod 2 printed the entire building, mostly using automated systems. However, it’s essential to have an operator to monitor machine behaviour, coordination, deposition speed, and other technical factors.

In 3D printing construction, speed and flexibility are two major advantages. The machine is so smart that it can understand door and window placement based on the design and print the entire structure accordingly. And it’s not that the structure is weak; in fact, it’s six times stronger than normal brick walls.

The printer used in the Post Office project was imported from Denmark and used raw materials, including 30% fly ash, which significantly reduces noise compared to traditional construction processes, providing an additional advantage. The entire concrete mixture was prepared on-site. As I mentioned, the entire system was automated, with the only manual part being the reinforcement, such as the steel structure.

It was possible to build walls up to 1 to 1.5 meters in height in a single day. A brief period was required after each layer to allow the previous layer to set before adding the next one.

MP Satish, the senior executive vice president of L&T, says that if the volume of the project increases, the project cost can be reduced by at least 20%. One of the major advantages of 3D printing is that even a project covering 100,000 square feet can be completed in less than six months.

The Prime Minister Of India is Even Involved

Prime Minister Narendra Modi also shared the achievement of this project on his Twitter handle. He wrote: “Every Indian would be proud to see India’s first 3D printed Post Office at Cambridge Layout, Bengaluru. A testament to our nation’s innovation and progress, it also embodies the spirit of a self-reliant India. Compliments to those who have worked hard in ensuring the Post Office’s completion.”

Other 3D Printed Construction Projects in India

Several other structures have also been built using 3D printing. TVASTA Constructions has completed two projects using 3D printing – a 3D printed bus shelter and a statue. In the bus shelter project, 30% recycled concrete aggregates were used, and the project was completed in just one week.

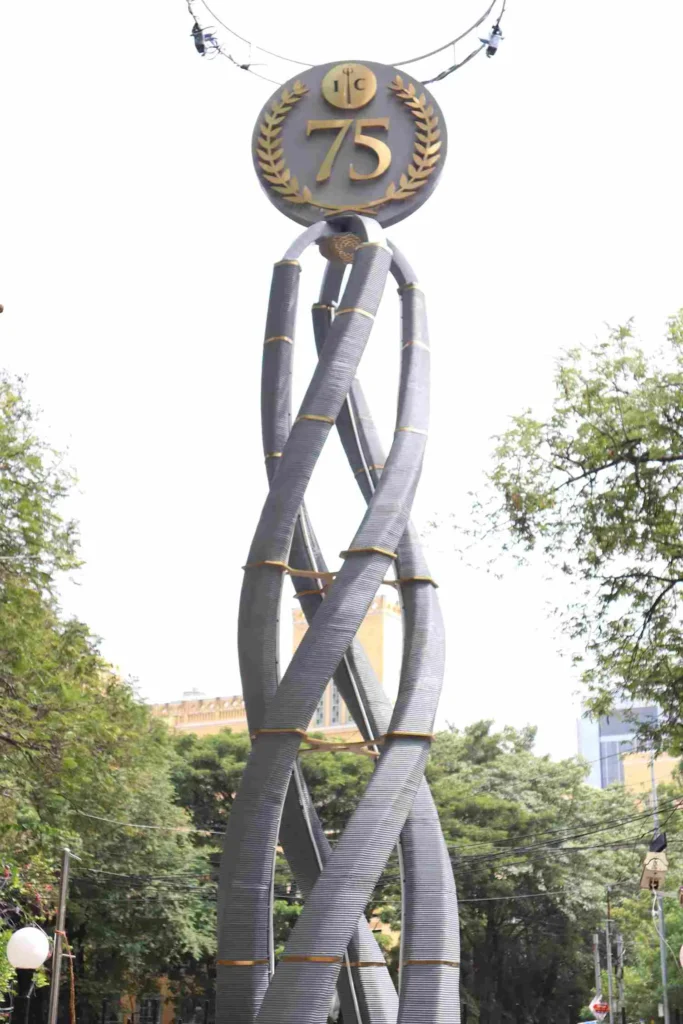

The statue, named Anant Siras, was made to commemorate India Cement’s completion of 75 years. It took one month to assemble.

Additionally, there was another project called Amaze 28 in Thiruvananthapuram, Kerala, where a single hall building spread across 380 square feet was built using 3D printing technology.

In the Concluding Lines…

The advent of 3D printed houses marks a transformative leap in construction technology, offering unparalleled speed, cost-efficiency, and customization. With reduced waste and faster completion times, these innovative structures epitomize the future of sustainable and affordable housing solutions, heralding a new era of architectural possibilities.