Let’s say, I have two AMD RYZEN 7 3700X. Both the CPUs are the same, right? Well, not necessarily. Two CPUs from the same brand and the same lineup could be different especially when it comes to overclock because of the fabrication process, each and, every processor from the same lineup could be different. It’s not just about the processors; GPU, VRAM, RAM, and almost each and every semi-conductor component possesses the same story. So, what’s the reason for this inconsistency? The answer is in the manufacturing process. So, without further ado, let’s understand how chips are made? What is Silicon Lottery? and What is Binning?

Read Now: How to Install Chrome OS Flex on Your Windows PC & Laptop

How are Chips Made? How are CPUs Made?

If you’re thinking about the working principle of a CPU then it is hard to believe how it can perform so many tasks in such a small area. It looks like magic. No, it’s science. It’s the result of decades of brilliant engineering and research. Chip fabrication is way more complex method than you think. It’s performed at the microscopic level.

You might have an idea of what’s inside a CPU? Yes, transistors – billions of billions transistors are packed in that small package. As processors are getting powerful over the years, gaps between the transistors and the size of the transistors are constantly decreasing and in that same area, more transistors are packed in.

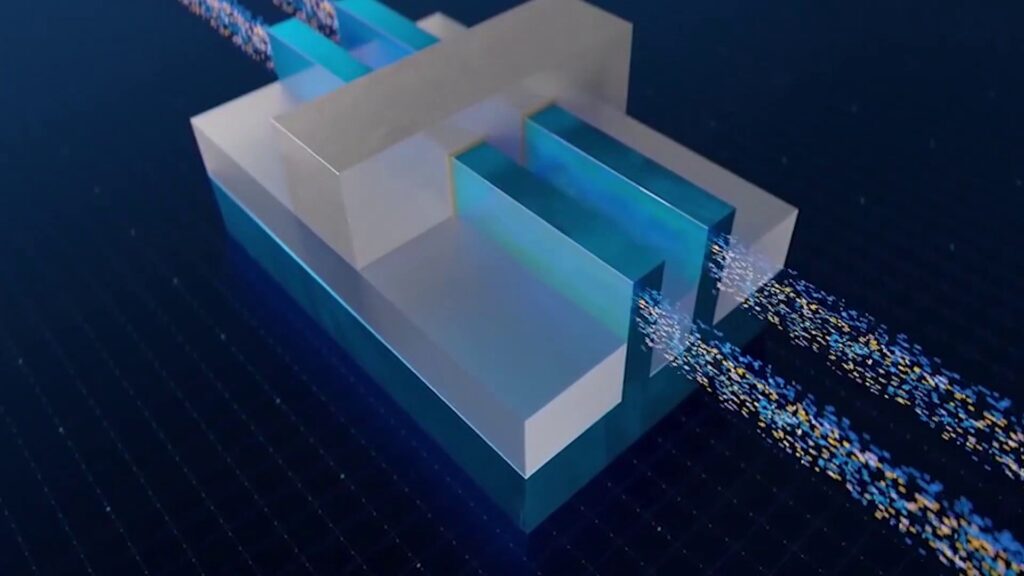

Transistors are impossibly small that even precision lathes, CNC machines, and even 3D printers that could work in micrometer aren’t precise enough to fabricate the transistors in the CPU. Today’s chips are built in nanometers. That’s 1000000000 times smaller than 1 meter. That’s why, Photolithography comes into place and solves the issue. Instead of mechanical solutions, Photolithography uses light.

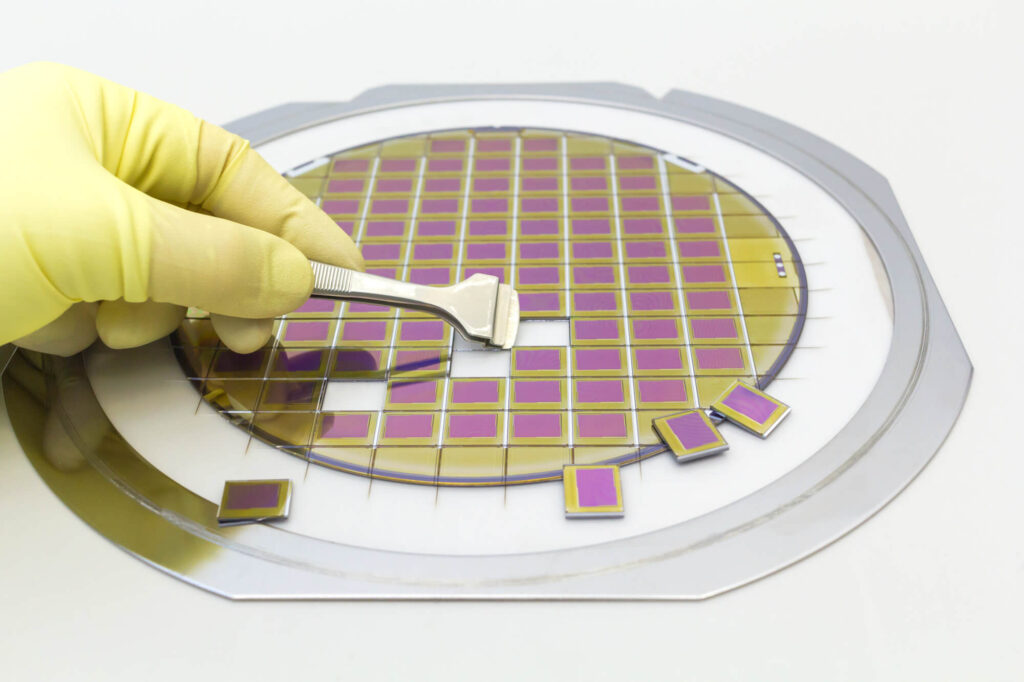

Can you remember the old projectors? Those enlarge the image and project it on a wall or something similar. Photolithography is almost the same technique but in a reverse way. UV light passes through the Stencil (which has the design of the processor) and then through a few lenses. These lenses shrink down the image way smaller than the actual size of the Stencil. This image is then projected on a silicon wafer. Before the projection, the wafer is coated with a photoresist which responses to UV light.

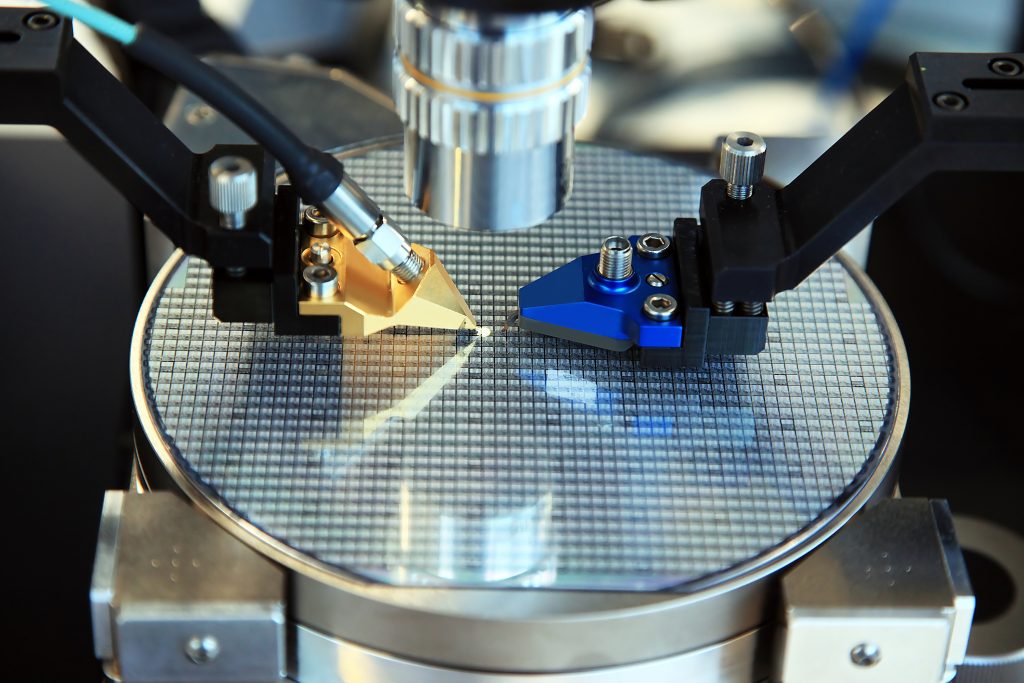

The light is projected through the Stencil on the photoresist and it gets hard, can’t be removed and unexposed portion will be washed out and that gap then fills with copper and also with the use of Doping, the transistors are formed. This process could be done multiple times to gain the needed result. In a one silicon wafer, multiple chips are formed. Later then, they are cut into pieces with a fine saw and then are packed depending upon their performance. From a silicon wafer, 70% to 90% yield can be used and the rest is getting wasted for different manufacturing defects.

All of these were done in an extremely controlled 99.99999% dust-free environment. A single piece of dust on a wafer could damage the wafer and causes a loss of thousands of dollar.

In Nano-Scale, there are Some Serious Issues

When transistors are designed in a few nanometers then sometimes there could be some serious problems. Transistors should be supposed to stop and flow electricity depending upon the current applies on ‘Base’. Because of their small size, sometimes in a chip, one or few transistors can’t block the electricity so electrons could easily flow through them. This is called Quantum Tunneling

Binning is Necessary

As I mentioned earlier, in a silicon wafer, many Chips are formed. And in a nanoscale, defects in that chips are pretty common. Believe it or not, no matter what, the classification of the processor is, all processors are formed from the same silicon wafer and also from the same blueprint. For instance, a budget range core i3 processor is formed from the same wafer where a Core i9 10900 was picked. This is done to reduce the wastage of the chips. All chips of a wafer are not equally formed. Some perform just like expected but a few do lower or way lower than that.

After the cutting process, chips are classified depending on their performance. For example, if the defect is formed in one or multiple cores then those damaged cores are disabled and that chip will be sold as a lower-end model and of course at a lower price. If the defect is in the vital components something like in the Cache Memory then the Chip is thrown out to the garbage.

Let’s say, in a silicon wafer, all chips are designed to be an i9 processor. For that, they suppose to meet the requirements. As I said, in nanoscale, it is possible that some or a few chips are getting defective. Although, in that wafer, there will be some chips that will perform what they suppose to do and some may perform way better than the standard. The defective chips are then sorted out. Then they find out the problem. If in a chip 2 cores are not working well then those two are disabled and the chip is kept for i7 processor. Similarly, If only 4 cores are working perfectly then that chip will be sold labeled as i3. This process is called Binning.

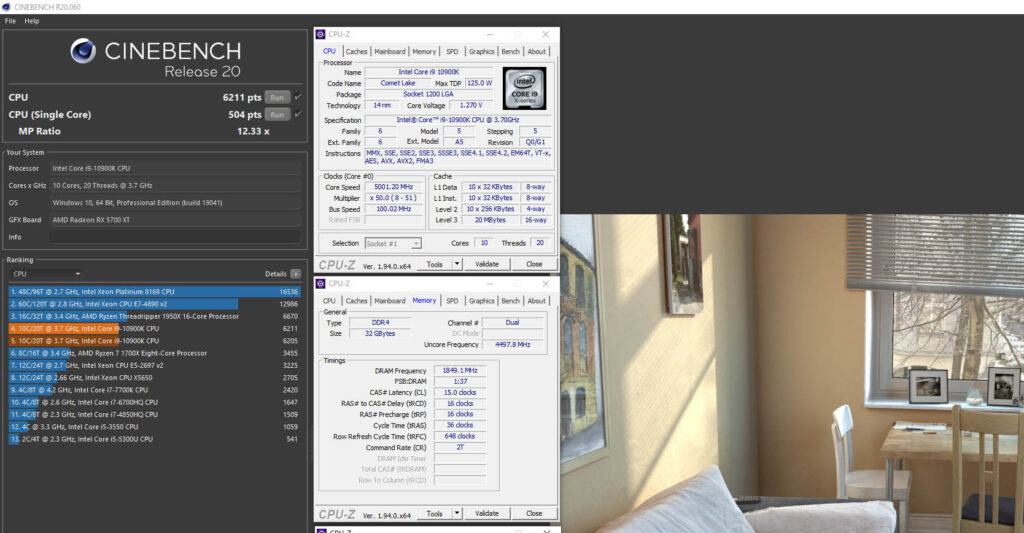

Binning can go both ways. If a chip is performed better than expected then that chip will be sold at a higher price tag. A good example of this is the Intel K series. K series CPUs are almost identical to their non-K counterparts but their main difference is in the clock speed. They can achieve higher clock speed and even they are overclock-able. It’s also a fact that not all the K-labeled CPUs are the same. You have seen that some i9 10900K could go beyond 5GHz and some cannot achieve that frequency.

Generally, on a silicon wafer, chips that are printed center have fewer defects and offer the best performance and low heat production. As we move to the edges of the wafer, their quality degrades.

After cutting the chips from the wafer, manufacturer test the chips and when they find that a few chips don’t meet the requirements for what they were designed for then those chips will be binned out for lower-end products. Same story for RAM, GPU, VRAM, and almost each and every semiconductor component.

What is Silicon Lottery?

Until now, I have talked about how CPUs are made but as an end-user when we are going to buy a processor, we never know the quality of the chip of that processor – from which location of the wafer the chip was cut and the quality of that chip. It’s completely on your luck. If you’re lucky enough then you may get the best chip from the market. That not only offers high clock speed, high efficiency, and lower heat production but also that chip will have a higher lifespan.

For instance, one Core i9-10900K processor may overclock to 5GHz, while another hardly achieves 4.5GHz. When we will going to purchase, we have no way of knowing which CPUs overclock better. If you pick up the better one, you will win the “silicon lottery.” Yes, this is actually the silicon lottery. Nothing much. If you’re lucky then you will get the best product from the market.

Don’t Copy Overclock Settings

Every chip is different so we should not replicate the same overclock settings in two same processors. At a certain voltage and clock, one processor is running completely stable but another processor from the same brand and same line-up is just overheating and becoming unstable. In that case, it’s possible to improve the CPU cooler to get the stability but in some cases, there are no heating issues as the CPU just does not want to achieve that clock and becomes unstable. The same thing happens for RAM, VRAM, and even GPUs. By following one’s overclock settings, you can get the idea but you need to find your own settings for your component.

Cooling Is Also Important

If you really want to overclock then choosing the right cooling solution is definitely important. Even If you won the silicon lottery still without the right cooling, your processor doesn’t achieve the higher clock speed. Thermal performance is always a limiting factor of overclocking. If you are unable to cool the CPU properly, it heats up and to a certain degree, it will underclock itself.

Also Read: 2.5 Vs 3.5 HDD: What is Better & Why?

If you have not seen those videos then let me tell you, enthusiasts have managed to overclock CPUs to 8.1GHz by using liquid nitrogen. Here’s a video regarding that.

Hope you guys enjoyed this article and learned a few things. If so then don’t forget to express your opinion in the comment section below. Thanks for visiting.