We have already talked about 3D printed rockets, and now we’re talking about using 3D printing to build homes on Mars. Mars is our Earth’s nearest planet. Its atmosphere is made up of 95% unbreathable carbon dioxide. The average temperature on the red planet is -80 degrees Celsius, dropping to -220 degrees Celsius at night. So, extreme weather conditions exist there. Despite being the nearest planet, it takes about 9 months to reach there.

Human Habitats on Mars

So far, humans have not been able to reach Mars; only robots have been there. However, NASA says that by 2030, humans will go there for research and exploration. There is a need for a home where astronauts can stay safe.

The solution to this problem has been found using 3D printing. A 3D printed habitat will be prepared on the Red Planet. Raw materials will mostly be gathered from Mars itself, primarily using Martian rock and plant-based polymers.

Basics Of 3D Printing

3D printing, also known as additive manufacturing, constructs three-dimensional objects layer by layer from a digital model. The process typically involves these key steps:

Designing a Model

Creation of a 3D model using computer-aided design (CAD) software or by 3D scanning an existing object.

Slicing

The 3D model is sliced into thin horizontal layers using slicing software. This prepares the model for printing by providing instructions for the printer’s movements and material deposition.

Printing

The 3D printer reads the sliced file and starts building the object layer by layer. Various printing technologies exist, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each using different materials and methods to create the object.

Post-processing

After printing, the object might require support removal, cleaning, curing (in the case of resin-based prints), and finishing touches to achieve the desired appearance and functionality.

3D Printing House

Using 3D printing technology, it’s possible to print anything from simple plastic pieces to rocket parts. Even for building houses, 3D printing is being used, which turns out to be quite cost-effective.

In India, this has also started. In the state of Kerala, Thiruvananthapuram, a building named ‘Amaze 28’ has been created, completely 3D printed.”

3D Printed Homes On Mars

“If we want to build a 3D printed house on Earth, we can find all the necessary things right here. However, if we want to build a 3D printed habitat on Mars, we’ll need to do something different so that we minimize the need to bring things from Earth. That’s why materials that can easily be found on Mars will be used.

With the current available technology, it’s nearly impossible to transport a large amount of cargo to Mars. The distance to Mars is not just a stone’s throw away; it’s average 225 million kilometers away. Even if NASA needs to transport just 2 pounds of cargo, it costs around $54,000. The lesser the payload of the rocket, the lower the cost.

AI Space Factory’s 3D Printed Habitats

Talking about the 3D printed house on Mars, there’s a New York-based architecture company called AI Space Factory that has designed a 3D printed house capable of handling Mars’ extreme temperatures, radiation and low air pressure.

Mars has a thin atmosphere and low air pressure, but this house will maintain habitable air pressure. If the house isn’t properly built, due to this pressure difference, the entire structure could inflate like a balloon. However, the double-walled design of this house will prevent that from happening.

Mars have higher levels of radiation compared to Earth. The atmosphere on Mars is much thinner than Earth’s, which means there’s less protection from cosmic radiation. The lack of a strong magnetic field like Earth’s also contributes to higher radiation levels on the Martian surface. This increased radiation exposure is one of the challenges that astronauts would face during extended stays on Mars that could cause cancer and premature deaths. This 3D printed house built by AI Space factory also can protect people inside from the solar radiations.

This 3D printed habitat is named ‘Marsha’ and is an egg-shaped structure. You might have seen dome-shaped structures in ‘The Martian’ movie, but according to AI Space Factory, this egg-shaped construction is the most structurally efficient form, especially when you want to minimize the use of necessary construction materials.”

Natural Light Source

“For the structural strength of the 3D printed egg-shaped structure, very little space has been allocated for windows, but there’s a skylight on top. It filters light down to reach every room below, providing sufficient natural light.

There are a total of 4 floors serving different purposes. It includes living quarters for 4 astronauts, dining areas, private spaces, an exercise and entertainment corner, dry labs, wet labs, and a garage for exploration rovers—basically everything. The interior is just like Earth; astronauts won’t even feel like they’re on Mars. Honestly, the interior showcased here is unlike anything I have in my own home.

Room to Room move

The curved structure incorporates stairways, enabling residents to transition seamlessly between different levels.

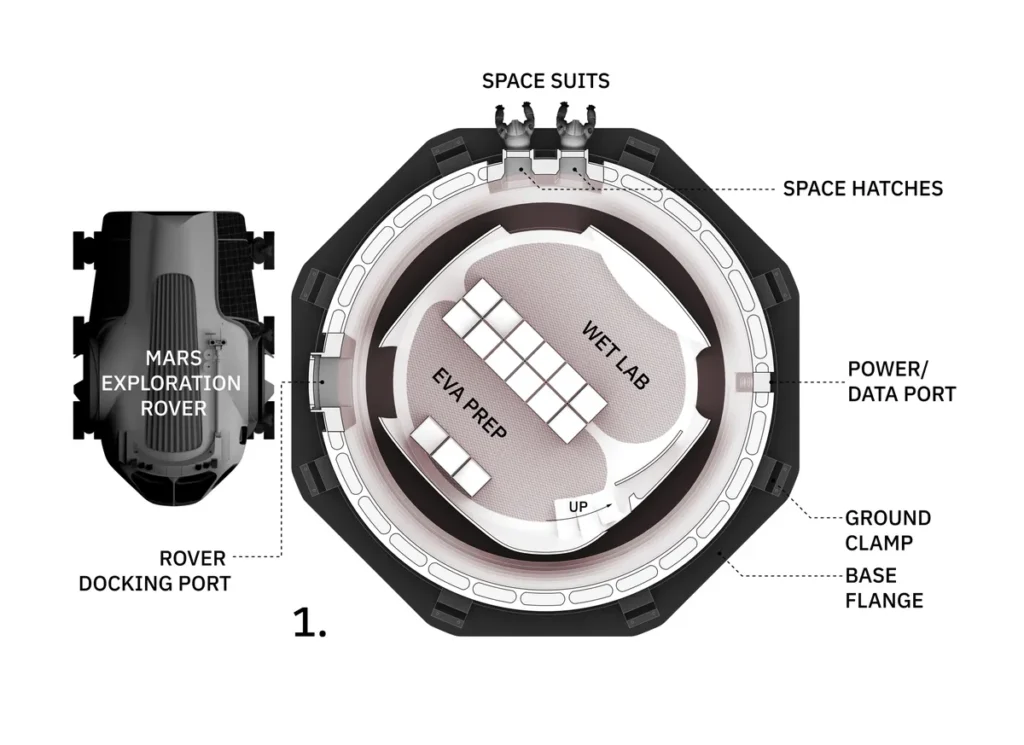

The ground floor

On the ground level, Marsha has a garage and wet lab with space for inhabitants to work. On the ground floor, there’s a designated area for EVA prep, serving as a preparation zone for astronauts gearing up for “extravehicular activities” in the Martian environment.

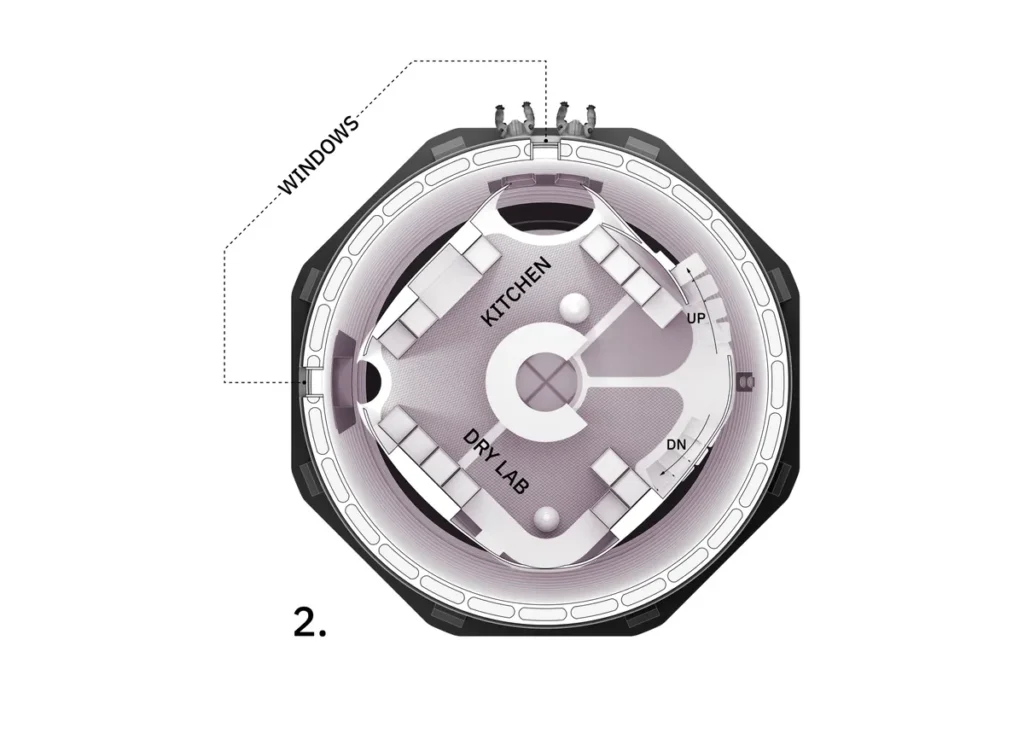

The second floor

On the second floor, there’s increased communal space hosting a kitchen and dry lab. Adjacent to the kitchen, the office area is situated. While one might not anticipate gourmet three-course meals, you might still prepare food grown on Mars.

The third floor

On the third floor, there’s a garden, sanitation pod, and private quarters for the residents. AI SpaceFactory prioritized designing a space that felt organic and centered around human needs, emphasizing the importance of private areas for rejuvenation.

Private space

Within one of Marsha’s personal pods, AI SpaceFactory envisions that even on Mars, there’ll be opportunities for video chatting with friends, emphasizing the importance of staying connected.

The top floor

The fourth floor of Marsha features a shared recreational and fitness area that maximizes natural light streaming in through the skylight above.

Work, Rest & Play

AI Space Factory aimed to design a space where inhabitants could find solace despite the isolation likely faced during travel to Mars, allowing for moments of relaxation and downtime.

In the Concluding Lines…

Overall, seeing this truly amazes me at how much 3D printing technology has advanced. Building houses on Mars with the help of robots—everything is automated. It feels like we’ll soon start living on planets other than Earth, becoming an interplanetary species.”